An Integrated Scanning Tool for Multiple HP Business Scenarios

Scanning is a business process which basically involves scanning of important content converted into Bar codes which are generally on products, labels, Boxes or Cartons. This paper is a narration of the new scanning tool developed by us that would act as a single Scanning tool for multiple business Scenarios. This is done to perform validations by comparing the data on the physical item to the data captured in the system and also capture the information in a quick way.Scanning is used in different business process and we have developed a single Scanning tool to cater to these multiple business Scenarios. This tool is extremely user friendly and flexible.

The major challenge in Ship9kVHS Project was to understand the existing functionality in the system which had been constantly developed/modified over 12 Years and develop the same functionality which is simple and flexible in the end-to-end solution in RSAP. The Complexity in scanning Process is to incorporating many and complex scenarios in single Custom screen and the performance required was 4 to 4.5 seconds for a single scan.

Problem Statement

The Scanning Process needed to involve incorporating multiple complex scenarios in single screen and also the stress has been on the performance which is a big challenge as the time consumed in the process to synchronizing data between SAP and Scanner per scan should be 2 to 3 seconds

Our Solution

The Solution is designed to integrate and manage all the Business scenarios in single custom screen with the scanning time involved per scan restricted to not more than 3 seconds. They are multiple scans done for multiple labels at the same time using this screen.

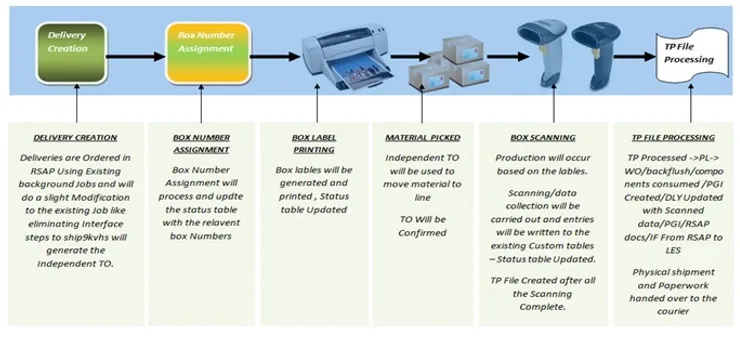

Delivery Creation takes place in SAP, after creating delivery a new output type will be triggered d for box assignment and the box numbers will be generated and assigned at the warehouse level and the status in the table ZG1_PCC_STATUS changed to PICK or LOAD. Or after TO Confirmation the status in the table changed to PICK. After that Label Printing with the output type then status in the table changed from PCIK to LABL. All the deliveries or Shiprefs will be picked with the status LABL and scanned, once scanning is over for the box, the status will be changed to REDY. After finishing Scanning TP File Processing will be done and the status changed to PGI.

Evidence that the Solution works

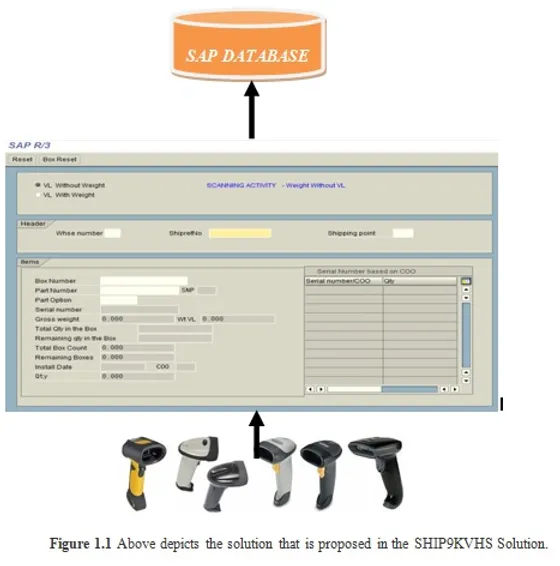

We have developed our proposed solution within the RSAP Development Instance using the dialog programming in SAP. The Solution is developed to incorporate all the business scenarios in Single Screen Scanning Process which is shown above. The two Scenarios’ are with Weight VL and VL Without weight. Again In Weight VL and Without VL we have two scenarios in each Serialized and Non-Serialized Process. In this Process we have 7 Scenarios each for Weight with VL and Weight Without VL. Total 14 Scenarios are incorporated in Single Screen in the Scanning tool and all the Process are showed as below.

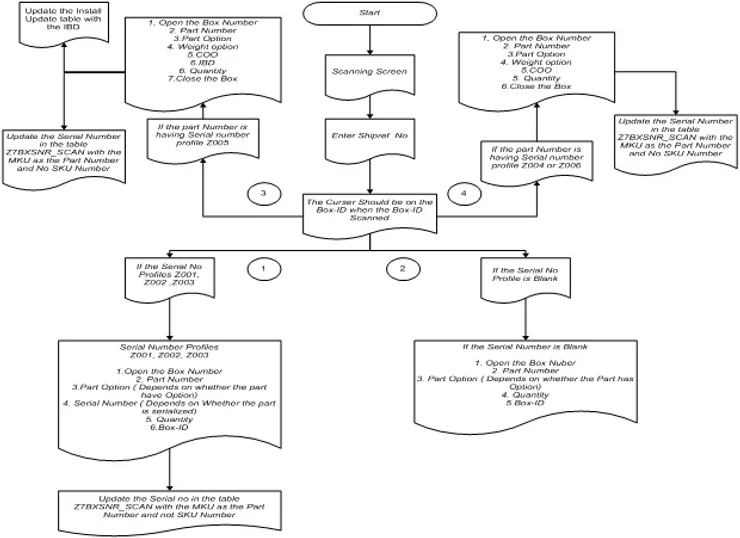

Scenarios 1,2 and 3 are defined If the Serial Number Profile are Z001, Z002 and Z003, Scenario 4 is defined If the Serial Number profile is Blank, Scenario 5 is defined If the Serial Number Profile is Z005, then the parts are treated as Country of Origin parts and Scenario 6, 7 are defined If the Serial Number Profiles are Z004 and Z006, Then the parts are treated as Country of Origin Parts.

Competitive Approaches

The Whole end-to-end scenario takes around 4 seconds to Complete scanning for 1 box. With this project Implementation 9.1 Million dollars worth of Orders delivered everyday without much effort with the this Solution. All the Interfaces with the legacy systems are removed, the Scanning status file interface with the SAP has been removed, and updating the changes to material master, BOM, Unit of measure has been removed. SAP Scanning tool is taking around 4 to 4.5 Seconds in Compare with the 5 to 6 Seconds of the Legacy tool. In Legacy two screens are used for the scanning where as in SAP Tool all the 8 business process are tied into single screen and it is comfortable to the user. The below comparison shows the 23.8 FTE Savings Per Year with the New SAP tool for 25000 boxes of Scanning per day as Compared with the Legacy tool as follows.

The SHIP9KVHS Scanning Solution is gone to production and it is live in 12 Sites across Asia Pacific and retired Legacy Systems in all the 12 Asia Pacific Sites.